by D.V. Zhurba, V.M. Zhurba, V.P. Veiko, D.V. Pankin, M.V. Zhukov and A.E.Puisha

Scientific and Technical Journal of Information Technologies, Mechanics and Optics. 2025;25(2):179-189

https://doi.org/10.17586/2226-1494-2025-25-2-179-189

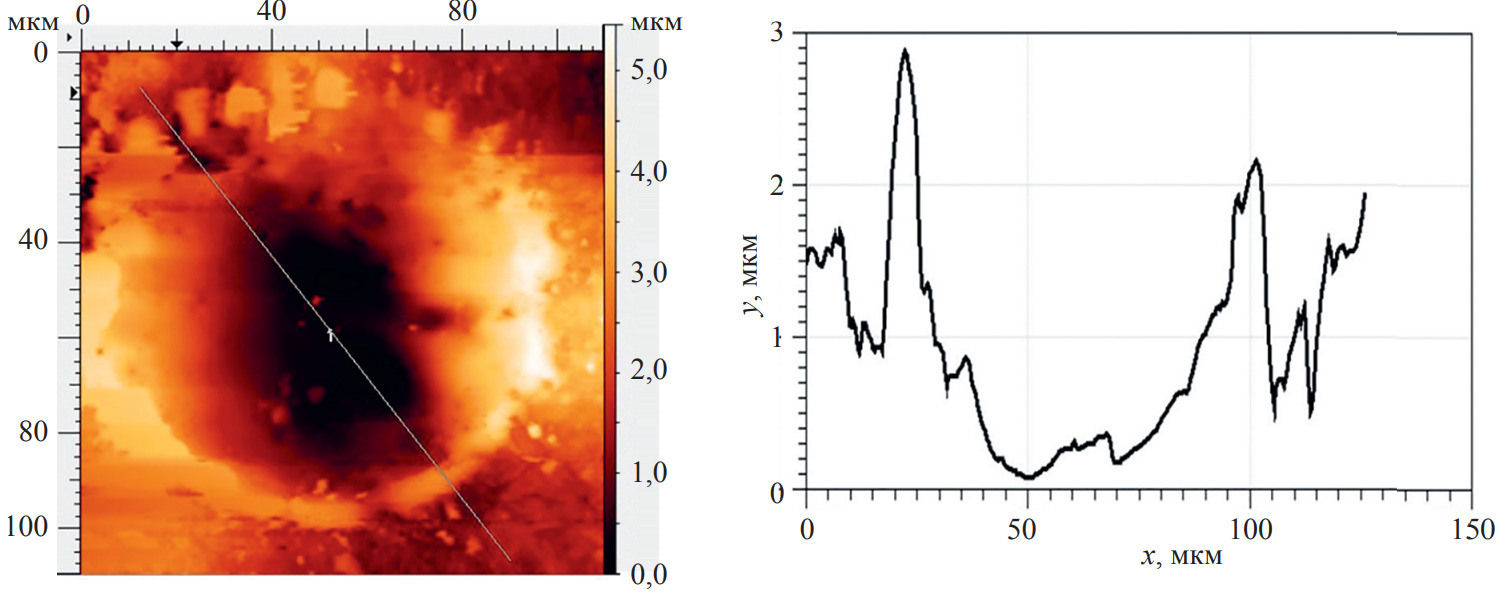

Phase transformations occurring in scale under the influence of nanosecond laser pulses have been studied. The initial phase composition of the scale and the phase composition of the surface layer subjected to laser exposure were determined. Surface treatment of the samples was carried out in the evaporative mode of laser exposure and led to scale ablation.

Two groups of samples made of hot-rolled carbon steel grade St3 (E235-C, Fe 360-C) sheet were studied. The first group consisted of samples with the original scale surface and samples with a mechanically polished surface. The phase and elemental compositions, as well as the morphological parameters of the initial scale, were investigated. The second group included samples with a scale surface treated with nanosecond laser pulses of a nanosecond ytterbium fiber laser with a maximum average power of 30 W. A two-coordinate scanning system based on galvanoscanners was used to scan the sample surfaces with the laser beam. The phase composition of the scale was determined by Raman spectroscopy. The morphological parameters of the surface and the elemental composition of the samples were studied using scanning electron microscopy, atomic force microscopy, and energy-dispersive analysis.

Studies of the initial scale phase composition showed that it mainly consists of magnetite, while wüstite was not detected in the scale composition. It was established that during scale treatment in evaporation mode, a crater is formed in the laser pulse exposure zone, the surface of which is covered with solidified molten scale. In the melt, a phase transformation occurs with the formation of wüstite. Upon solidification, the melt cracks, which is associated with the occurred phase transformation. It was shown that during laser cleaning, the evaporative mechanism of scale removal is accompanied by a phase transformation of a magnetite–metallic iron mixture into wustite. The obtained results can form the basis for the development of a new highly efficient technology for laser cleaning of steel surfaces from scale.