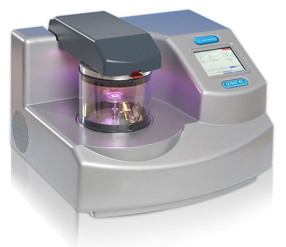

Q150T ES – universal system allows to operate as a deposition of metals, and in the mode of carbon deposition. Relevant consoles can be easily changed, and intelligent system automatically recognizes which prefix is inserted and displays the information on the screen.

Sputter system Q150T represents a single unit installation convenient form. Color touch screen allows several users to enter and keep the minutes of spraying. This innovation is aimed at users with little experience of using coaters, which easily will be able to enter and store data as well as select existing settings spraying. The system contains all the components work, including high-yield turbomolecular pump with air cooling and the possibility of pumping up to 70 l/sec. Automatic control system provides optimum vacuum conditions during deposition.

The vacuum chamber is a glass cylinder with an outer diameter of 165mm and a built-in shock protection. Q150T has the function "Exposure of the vacuum" which keeps the vacuum in the chamber after the deposition process has been suspended or ended. Except for multi-turntable, which is included in the base system can be retrofitted napylitel other tables from the list of accessories.

1. The working chamber of borosilicate glass with an internal diameter of 150 mm and a height of 127 mm pumped turbo molecular pump.

2. The presence of internal protective screen PEF.

3. Having a colored touch screen.

4. Pirani vacuum gauge (scale).

5. Vacuum maintained at spraying largest 5∙10-1-5∙10-3 mbar.

6. Sample holder – a rotating diameter of 60 mm, the rotational speed of 8-20 / min.

7. Target for sputtering chrome disc diameter 57 mm, thickness of 0.3 mm.