Multi-Jet Modelling (MJM) technology is a proprietary additive manufacturing method patented by 3D-systems and used in the line of professional ProJet™ printers. Models are built in layers using a printer head with several hundreds of nozzles. The MJM technology allows for simultaneous two-materials printing: in the build material (the photopolymer in this case) and in low melting point wax (used as a support filament for overhanging features). Each layer is exposed to the UV light for curing (solidification). After printing the model is placed in a special oven that melts and drains wax supports. The MJM technology allows to build accurate, high-definition models.

ProJet™ 3510 SD printer uses proprietary VisiJet materials: VisiJet M3 Crystal (build material) and VisiJet S300 (support material). It prints to a resolution of 375, 375, 790 dpi along X-, Y-, Z- axes respectively.

Features

- Printing technology – MJM.

- Print area (L x W x H) – 298 x 185 x 203 mm.

- Printing material – photocurable plastic.

- Layer thickness – 32 micron.

- High resolution.

- Automatic support generation using low melting point wax.

- File type: stl, ctl.

VisiJet M3 Crystal

VisiJet M3 Crystal is a translucent tough plastic material. It meets the requirements for USP Class VI certification, including biocompatibility for healthcare applications.

Specifications

|

Density @ 80°C (liquid) |

1.02 g/cc |

|

Tensile strength |

42.4 MPa |

|

Elastic modulus |

1 463 MPa |

|

Elongation at fracture |

6.83% |

|

Flexural strength |

49 MPa |

|

Heat distortion temperature |

56°C |

VisiJet S300

VisiJet S300 is a non-toxic wax support material. Melting point – 60°C.

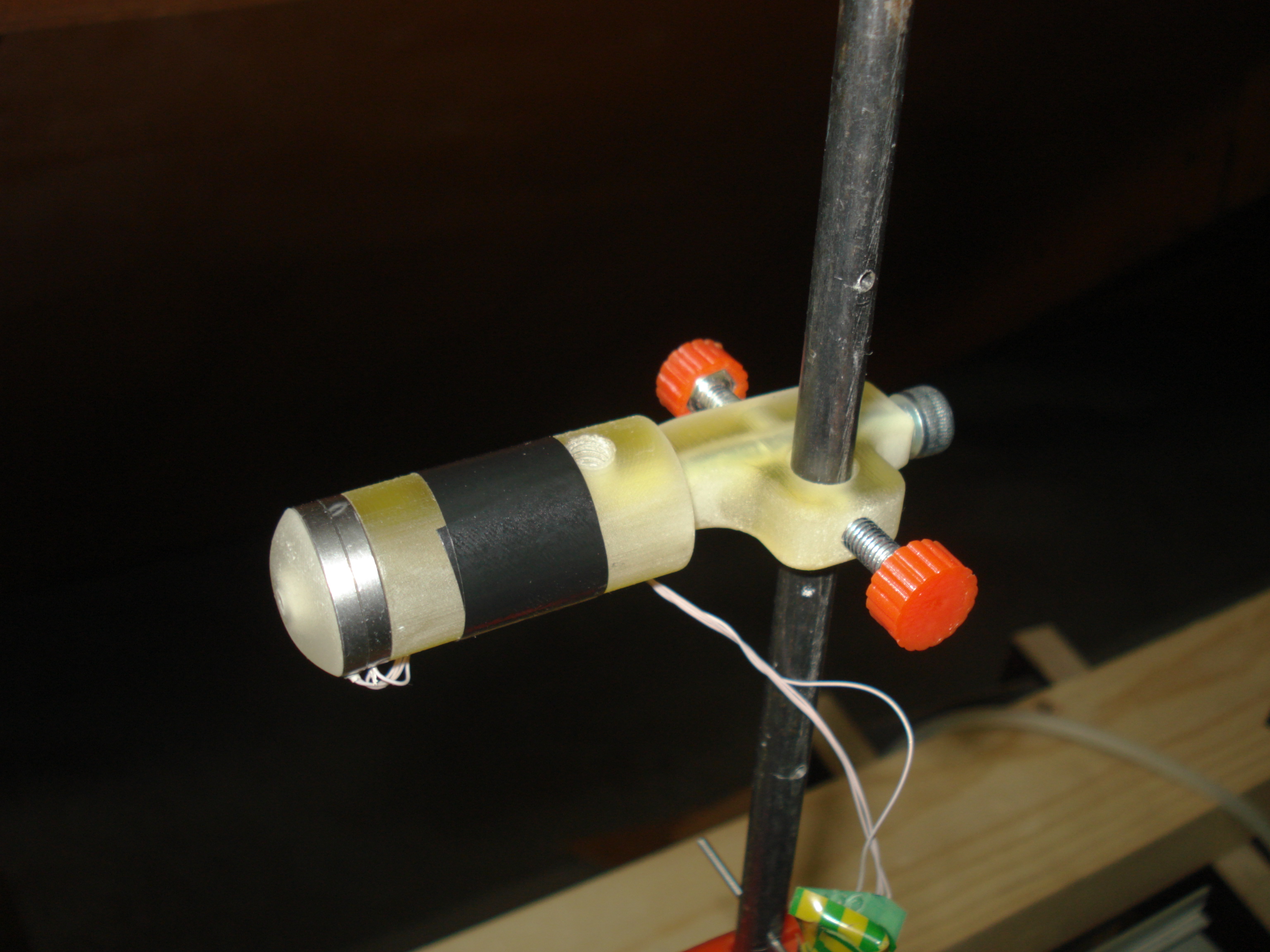

Examples of printed models

|

|

| An adapter for mounting DMI-0,1 pressure sensor. | A wheel for an educational stand (painted). |

|

|

| A model of Boeing 737 (consists of four parts with the wingspan of 50cm). |