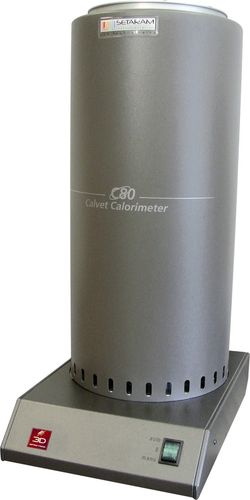

The C80 Calorimeter is one of the most powerful, yet flexible calorimeters available. The high precision Calvet detector offers a unique level of sensitivity to thermal events and also the ability to design cells and vessels to simulate almost any potential condition

The C80 uses the latest evolution of the Calvet Design calorimetric detector in which a sample and reference cell are totally surrounded by an array of thermocouple detectors allowing for the measurement of all heat evolved (or adsorbed) including radiation, convection or conduction. The Calvet detector is up to 94% efficient whereas typical plate DSC are between 20-40%, and as such the C80 provides for an unparallel precision of measurement independent of sample nature or matrix – solid, liquid, gas, powder etc.

The calibration of any calorimetric detector is a key parameter in it’s performance and with the Calvet detector the so-called Joule effect or electrical calibration, is used. A dedicated vessel with a built-in electrical heater (platinum resistance) is used to simulate the experimental vessel containing the sample, and calibration is carried out using a series of precise heat inputs. The main advantages of this type of calibration: It is an absolute calibration and not needed to use metallic reference materials. The calibration can be performed at a constant temperature, or in scanning (either heating or cooling).

There is a wide range of vessels available for the C80 calorimeter. The cells can be closed (batch type) or combined with fittings to introduce reactive agents (flow type). All the cells can be used either in isothermal or DSC mode.

Batch Cell - for investigations on solids or liquids: transformation, decomposition, thermal behaviour, heat capacity of solid (a specific cell is available to measure heat capacity of liquid) studies.

Gas Circulation Vessel - to study the effect of a gaseous atmosphere on a liquid or solid sample, oxidation, reduction, adsorption, hydrogenation or impact of controlled humidity.

Membrane Mixing Cell - to study the mixing of two substances (solid or liquid) in order to measure the corresponding heat of interaction (especially adapted to viscous or heterogeneous mixtures)

Reversal Mixing Сell - to study the mixing of two substances (solid or liquid) in order to measure the corresponding heat of interaction.

Ampoule Mixing Cell - for studying reaction between a powder and a liquid (mainly wetting or hydration).

High Pressure Batch Cell - the High Pressure cell is used when the sample evolves pressure, through a decomposition for example. For investigations on solids or liquids: transformation, decomposition, thermal behaviour, heat capacity of solid (a specific cell is available to measure heat capacity of liquid) studies

Cell with Pressure Transducer - to record simultaneously the heat and pressure released by a sample. There is no need to control the pressure.

Process Safety Cell - to evaluate the synthesis reaction followed by product decomposition in a single experiment

Controlled Static High Pressure Cell - to work under controlled and static pressure using a gas panel, to study gas hydrates formation/dissociation, to study adsorption and desorption

Controlled Dynamic High Pressure Cell - to work under dynamic mode (controlled pressure increase or decrease).

Setaram С80 Specifications |

|

|

Temperature range |

ambient - 300°C |

|

Temperature accuracy |

+/- 0.1°C |

|

Temperature precision |

+/- 0.05°C |

|

Programmable temperature scanning rate (heating and cooling) |

0.001-2°C/min |

|

Enthalpy accuracy |

+/- 1% |

|

Calorimetric Precision |

+/- 0.1% |

|

Sensitivity (Joule effect at 30 °C) |

30 μV/mW |

|

Resolution |

0.10 μW |

|

Cells (standard) |

12.5 ml |

|

Pressure (measured & controlled) |

350 - 600 - 1000 bar |

Image source: