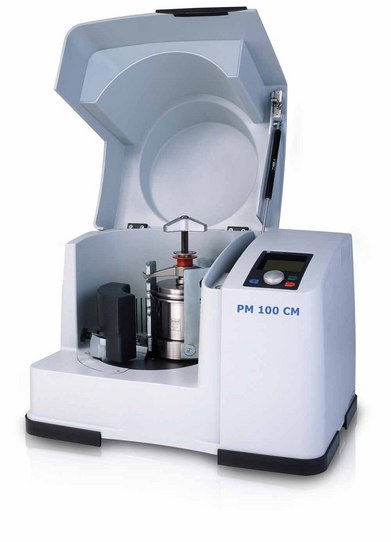

Planetary Ball Mill PM 100 CM used for chopping, mixing, homogenizing, colloidal grinding. The maximum rotational speed of the planetary disk to 650 rev/min.

PM 100 CM is a handy desktop model with one grinding station. She works in a centrifugal mode, allowing for a more gentle grinding with less wear of the grinding set. Grinding jar is placed outside the center of the planetary ball mill drive. The direction of rotation is opposite to the rotation of the sun wheel of the grinding bowl with a speed ratio of 1:-1 . Grinding balls in the grinding bowl exposed the so-called Coriolis forces. Speed difference between the balls and grinding jars produces an interaction between frictional and impact forces, which release more kinetic energy. The interaction of these forces leads to a high degree of grinding in a planetary ball mill.

Key Features

The use of milling, mixing, homogenization, colloidal milling.

Scope agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals.

The starting material is soft, hard, brittle, fibrous – dry or wet.

Reduction principle impact, friction.

Original size * < 10 mm.

Final fineness * < 1 micron, for colloidal grinding < 0.1 microns.

Batch size / volume * max 1 x 220 ml, max 2 x 20 ml with structured cups at each other.

Number of grinding stations – 1.

Speed ratio – 1 : -1.

The speed of the planetary disc – 100-650 r/min.

Effective sun wheel diameter – 141 mm.

Type of grinding jars "comfort", with optional aeration covers and clamping devices.

Material grinding set hardened steel, stainless steel, tungsten carbide, agate, sintered alumina, zirconia.

Dimensions of the grinding cup – 12 mL / 25 mL / 50 mL / 80 mL / 125 mL / 250 mL / 500 mL.

Setting of grinding time – from 00:00:01 to 99:59:59.

Working with intervals yes, with reverse motion.

Duration of the interval – from 00:00:01 to 99:59:59.

Duration pause – from 00:00:01 to 99:59:59.

Stored parameter combinations – 10.

Measurement of energy input – yes.

RS-232 / RS-485.

Drive 3 – phase asynchronous motor with frequency converter.

Drive power – 750 W.